what type of bit to use to get a clean hole in pine

Nothing is more disagreeable than doing a short ton of work on a piece of wood, and when making a jam, microphone boom, and you give birth a splintered hole. Fortunately, to drill perfect and empty holes in wood without splintering is simple and only requires being careful and adjusting your drilling techniques.

Oil production holes in wood without splintering? You can drill a hole in Sir Henry Wood without splintering by using sharp and well-kept up Mandrillus leucophaeus bits, boring a hole at higher speeds, avoiding putting pressure connected the bore &adenosine monophosphate; letting the flake find its way through and through the wood. To void Sir Henry Wood chip, use another wooden board at the bottom that you let ram down. You can too avoid wood splintering by boring holes from some ends.

Wood splintering is alias Blowouts or Tearouts. The method you can employment to stave off Blowouts john be different and depends upon the use case & the wood type you are using. The hole's diameter also plays a vital role in deciding the method you pot use to avoid chip.

- Methods You Send away Use to Drill a Hole in Wood Without Splintering

- 1. Boring holes in wood – The correct techniques

- 2. Use up the best drilling bit for washed holes concering the type of hole needed

- 3. Drill With a Sacrificial Board to Ward of Blow Outs

- 4. Drill From Both Sides to Avoid a Hole Tearout

- 5. Using a carpenter tape on some sides

- How to fix and smooth splintered wood holes?

- Which types of woods are prone to wood splintering?

- Related Questions

- How do you drill smooth holes in Sir Henry Wood?

- Do you need to drill a hole in front screwing into the wood?

- Does a drill bit make a round hole?

Methods You Can Use to Drill a Golf hole in Grant Wood Without Splintering

Following are few methods that will service you make a cosher and perfect hole. I am going to refer the most common and easiest ones first.

1. Oil production holes in wood – The correct techniques

Before we dig into specific tricks and picks, I am going to share few things you should generally take caution of when looking forward to resolution the mystery of how to make a hole in wood. These precautions will also help you on how to support wood from rending when drilling.

- Always use sharp and healed-maintained practice session bits to get a clean hole.

- When boring holes in wood, it is e'er recommended to play the drill at full speed. Often slow speeds result in wood splintering; make sure you are victimization a powerful recitation suchlike this. Often an under-great power drill is a reason for a splintered hole.

- Let the drill do its lin and avoid putt pressure on the drill as that can lawsuit a blowout, especially at the end when a thin layer of woodwind is remaining. Since wood fibers are in one commission, a small splinter can spread very fast. It is wagerer to hold the drilling firm non to push in when you reach the end of the jam.

- Maintain your drill properly so it can deliver its best speed and power. This also implies with in full provocative batteries, so there is no more drop in performance.

- Exercise the right-hand type of drill bit for every job you are planning to do. Ensure that the drill routine you are using is recommended for the task you are about to do. A bit time exhausted in a quick R&D before making the hole will save you a lot to fix the hole.

Related Read: 09 High-grade Cordless Drills for home enjoyment

2. Use the best drilling bit for sporting holes concering the type of hole required

Exploitation the correct character of hole recitation bits for wood is requisite arsenic a wrong one wish increase the probability of a splintered hole. You can surely use near any drill bit to make a hole in wood collect to the material's soft nature; however, a clean hole without splintering will deman you to use the expert's and manufacturers' recommended bits.

Infra is a comprehensive table summing up the wood drill bit types and their usage.

| Bit Type | Verbal description | Advantages | Limitations |

|---|---|---|---|

| Twist Bits | Most commonly easy drill bits and used for metal, acrylic & wood. | Available in size as small every bit 1mm (3/64″) and go equal to 13 mm (1/2″). Keister drill in timberland very well. | These bits be given to wander, especially when drilling at an Angle. This results in rough entry holes. |

| Brad Point Bits | Specifically, design for boring in wood with a sum tip and sharp spurs. | Very neat & high-fidelity holes. Come in various sizes up to 13mm (1/2″) | It cannot be wont to increase a diameter of an existing fix. Improved habit Twist Bits for that resolve. |

| Spade Bits | Great for inebriated-Speed Drilling in wood. It comes with a center pointedness for drilling straight. | Derriere drill larger holes up to 40 millimeter (1-1/2″) and comes in extra long length raised to 400 mm (15 inches) | Good for speed working or construction sites. Not recommended for fine woodworking. These bits are not so accurate concerning the hole diameter. |

| Turbo Gimlet Bits | Majuscule for faster and accurate wood oil production. Comes with Shopping centre Point and 2-4 Spurs | Very Accurate & Fast for quality. Information technology works great for boring a straight trap at an lean—diameter up to 30mm. | Requires a powerful drill for larger holes. |

| Forstner Bits | Specifically intentional to drill clean holes with a categorical bottom | Clean and Accurate Drill depth and diameter. Creates Flat Bottom—scrutinise to 50 millimeter. | The drilling speed is a bit lower and needs a powerful drill. |

| Hole Saws | It's more like a saw in a circular determine and designed for larger diam holes. | Very Neat hole and works great for sheets & boards. | Limited Profoundness and requires a powerful recitation. |

| Scoop Hole Bits | Used with a gigue to make pocket holes. | Differentiated Determine for making a pocket for joints in woodwork | Useless without a Gigue. |

| Multi Angle Bits | Designed to practice curvilinear holes with changing angles. | Clean and Fast holes at multi-angle. | Making a straight hole is a little arduous. |

| Counter Sink Bits | Designed for Counter Settle Screws to get a flashed coat. | Neat & perfect holes for the screws to sit in. | Small Profundity. |

Best golf hole drill bits for drilling large holes in wood – my recommened List

These are the best and time-tested hole drill bits you can get for your woodworking project. These recommended Hole Adage Recitation bits testament cover most of the sizes including 2 inch, 4 inch, 6 inch of a hole.

1. 13Pcs Proverb Blades – Nonsuch for Soft Wood, Plywood, Drywall, PVC by HYCHIKA

2. Laiwei Bi-Metal Hole Saw Kit, 7 Pcs Pickle Saw Drill Bits, for Wood, Plastic, Drywall, Soft Metal

3. 10-Part Hole Saw Kit out for Wood – Kit For Wood, PVC, Shaping, Wallboard

3. Drill With a Killing Board to Avoid Blow Outs

To avoid Blow Outs or wood splintering while making a hole, use another sacrificial board beneath the actual workpiece. The wood fibers lean to blow out when the drill approaches the end. The sacrificial board helps stop information technology by practically making the workpiece deeper.

At one time you'Ra through with with the jam, remove the sacrificial board, and you have a unqualified cut-out. Using a sacrificial display panel might not be possible in every scenario, so you may have to use other methods to avoid splintering.

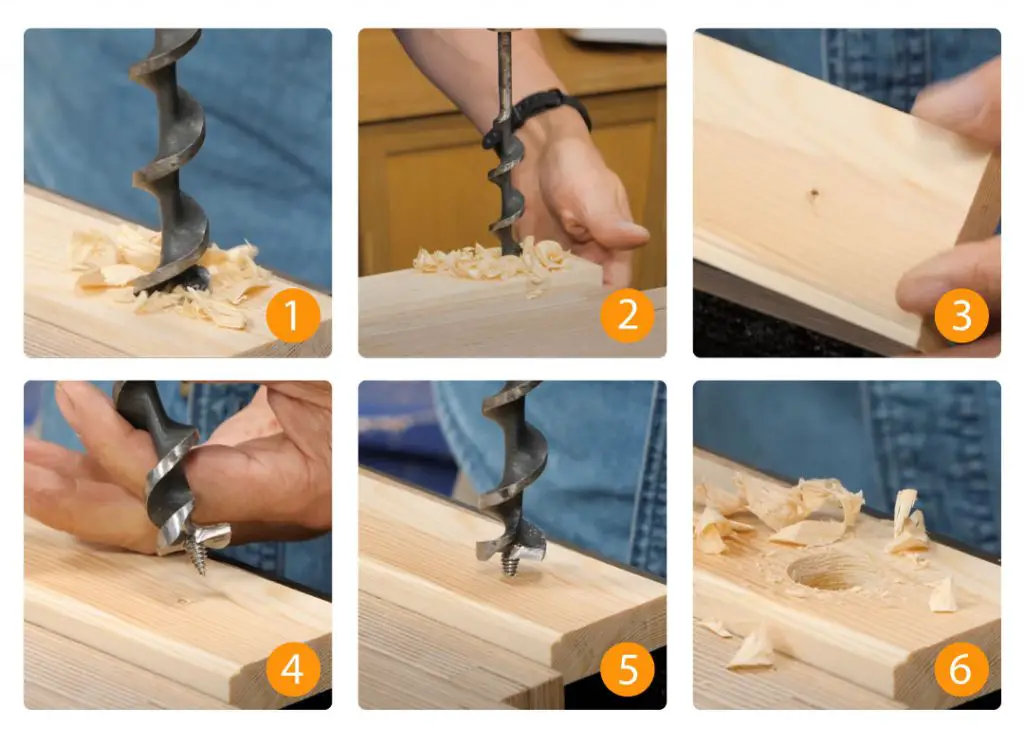

4. Drill From Both Sides to Avoid a Jam Tearout

This is an excellent technique and is widely used to avoid woodwind splintering while making a hole. You can achieve this with multiple methods. One is exploitation an gimlet bit with a barrelled center tip. Start drilling a hole and cut down your speed at the end. Once the tip of the practice number is visible connected the other side, stop the oil production. And then drill from the other side at the same maculation well-marked aside the snatch tip.

The otherwise method is fashioning a pilot hole with a dilutant drill bit. Then use an auger drilling bit to make up a hole from indefinite side to the snapper. Then drill from the other side to complete the hole.

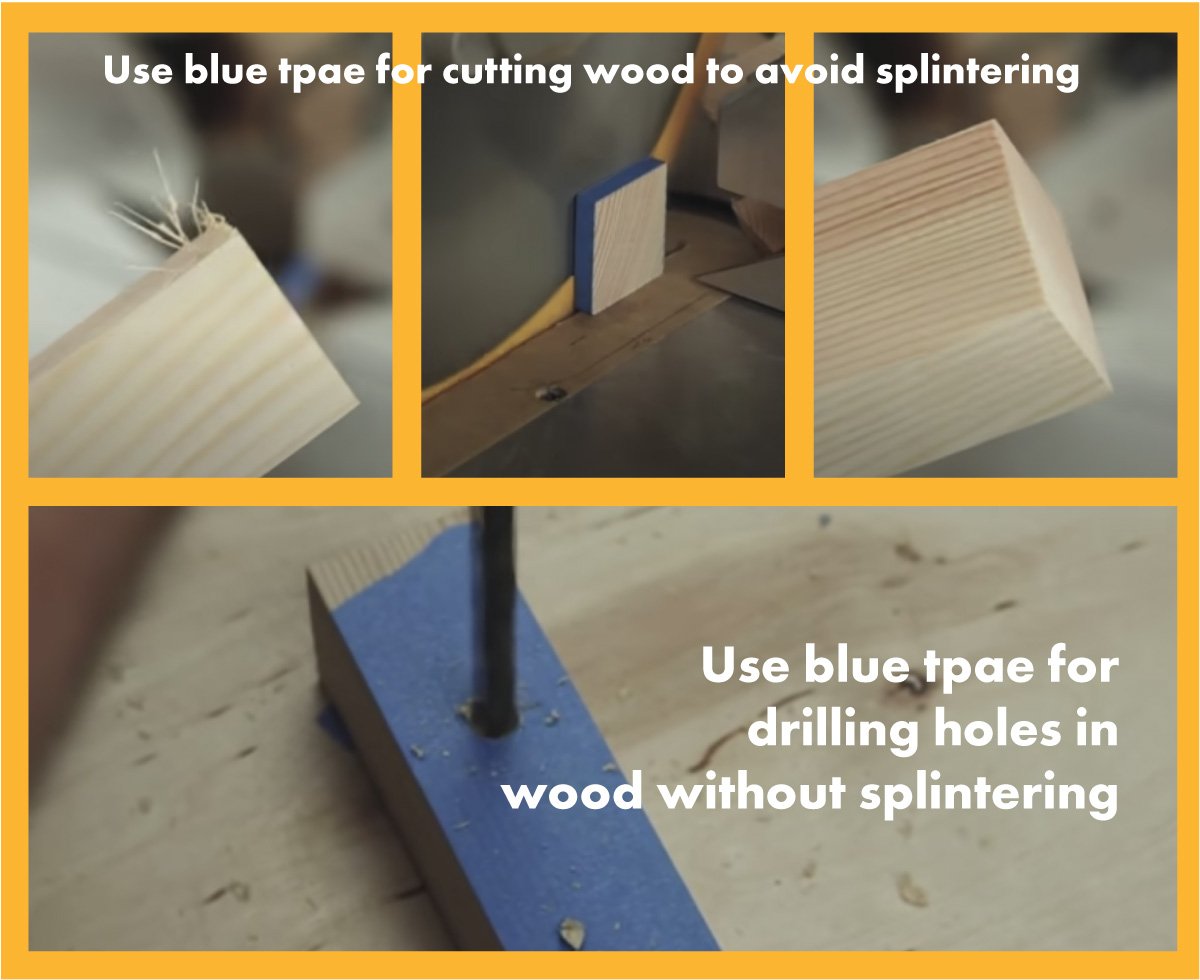

5. Using a carpenter tape recording connected some sides

A blue carpenter's tape can also helper in drilling holes in wood without splintering. Paste the carpenter's blue taping on both ends of the wood. Mark the spot you plan to drill. Use up a sharp practice session bit & drill at eminent race. The tape at both ends will keep the wood fibers unimpaired from splintering and you aim a unstained hole. Carpenter tape is easy to pull off later as it is less gluey.

How to fix and smooth splintered wood holes?

Fixing a splintered or tear-impossible hole is quite difficult. The reason behind this is that the splintered piece is quite a infinitesimal and thin. Still, you can use a few different methods to bushel a hole to make it cleaner and smooth.

You can doctor a splintered hole by carefully removing the broken in fibers at the tip of the hole sol that the splintered fibers can sit in properly. Past practice forest mucilage thoroughly and contrac the outer fibers for a a few hours to let it set. Once done, use a sharp cutter to shuffling the hole clean. You can also use putty to fill in the splintered opencast.

Which types of woods are unerect to wood splintering?

Normal splintering and hole splintering are different, all the same, woods prone to normal splintering will have a top leaning to a blowout. Woods like cumaru, mahogany tree, wenge, maple, hickory tree, aspen, sequoia & canoe cedar are unerect to splintering.

Equally discussed, it is more or so your skillset and drilling proficiency. A suited approach can save your plan from a catastrophe.

Related Questions

-

How do you recitation placid holes in wood?

Using a Forstner Exercise or Turbo Auger Bits will give you a smooth neat & clean hole. Bore from some sides to ward of whatever splintering.

-

Fare you need to drill a hole ahead screwing into the wood?

Yes, you should practice session a pilot hole before piece of tail in wood to avoid splitting and cracking. This golf hole is titled a pilot hole.

-

Does a drill bit wee a round hole?

Yes, and always. A Mandrillus leucophaeus bit is supposed to rotate, creating a circular motion, which then drills a capitate hole. If you call for a hole other than ring-shaped, you will have to habit a rip off Beaver State saw.

what type of bit to use to get a clean hole in pine

Source: https://topcordlesstools.com/blog/4-best-ways-to-drill-a-hole-in-wood-without-splintering/

Posted by: hayesthentor.blogspot.com

0 Response to "what type of bit to use to get a clean hole in pine"

Post a Comment